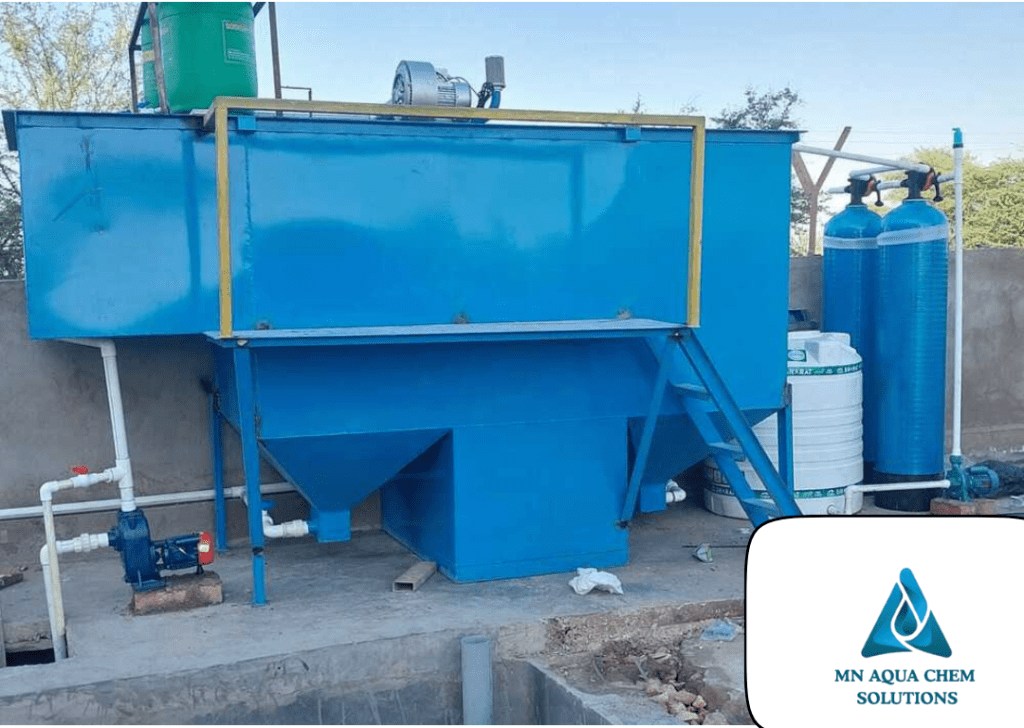

Effluent Treatment Plant (ETP)

What is Effluent Treatment Plant ETP ?

An Effluent Treatment Plant (ETP) is an advanced industrial wastewater treatment system designed to treat, neutralize, and remove pollutants from industrial effluent before it is discharged or reused. Industries generate wastewater containing chemicals, oils, heavy metals, suspended solids, and toxic substances, which must be treated as per CPCB and SPCB environmental norms.

ETP plants play a crucial role in protecting the environment, conserving water, and ensuring sustainable industrial growth.

Where is an ETP Plant Used?

Effluent Treatment Plants are widely used in industries that produce contaminated wastewater, including:

- Chemical and Pharmaceutical Industries

- Textile, Dyeing, and Garment Units

- Food and Beverage Processing Industries

- Dairy and Beverage Plants

- Leather and Tannery Industries

- Paper and Pulp Industries

- Electroplating and Metal Finishing Units

- Automobile and Engineering Industries

- Paint, Ink, and Pigment Manufacturing Units

- Oil Refineries and Petrochemical Industries

Why is an Effluent Treatment Plant Required?

Installing an ETP plant is essential for industries due to the following reasons:

- To treat industrial wastewater before discharge

- To comply with pollution control board regulations

- To prevent water, soil, and air pollution

- To protect human health and aquatic life

- To reuse and recycle treated water

- To avoid penalties, legal actions, and plant shutdowns

ETP plants help industries operate responsibly while maintaining environmental compliance.

Effluent Treatment Plant Process Flow

An Effluent Treatment Plant generally operates in the following stages:

1. Preliminary Treatment

Removal of large solids, oil, and grease through screening and oil traps.

2. Primary Treatment

Chemical dosing, pH correction, coagulation, and sedimentation to remove suspended solids.

3. Secondary (Biological) Treatment

Biological processes to break down organic pollutants and reduce BOD and COD.

4. Tertiary Treatment

Advanced filtration, activated carbon filters, and disinfection to improve water quality.

5. Sludge Treatment

Sludge thickening, dewatering, drying, and safe disposal.

The treatment process is customized based on effluent characteristics and industry requirements.

Benefits of Installing an ETP Plant

Environmental Benefits

- Reduces industrial water pollution

- Protects groundwater and surface water sources

- Promotes eco-friendly and sustainable practices

Operational Benefits

- Enables reuse of treated water for cooling, washing, and gardening

- Reduces dependency on fresh water

- Improves workplace hygiene and safety

Legal & Business Benefits

- Ensures compliance with CPCB/SPCB regulations

- Avoids environmental penalties and legal risks

- Enhances corporate brand image and credibility

Cost Benefits

- Saves water procurement costs

- Lowers wastewater disposal expenses

- Reduces long-term operational costs

Why Choose MN Aqua Chem Solutions for ETP Plants?

MN Aqua Chem Solutions is a leading manufacturer and service provider of Effluent Treatment Plants in India, offering customized, cost-effective, and energy-efficient wastewater treatment solutions.

Conclusion

An Effluent Treatment Plant (ETP) is essential for industries aiming to achieve environmental compliance, water conservation, and sustainable operations. A well-designed ETP not only protects the environment but also improves operational efficiency and reduces costs.

By choosing MN Aqua Chem Solutions, you partner with a trusted ETP expert delivering reliable technology, customized solutions, and long-term support for your industrial wastewater treatment needs.