Why Most Industrial Wastewater Treatment Plants Fail to Deliver Desired Results..

Many industries install an Effluent Treatment Plant (ETP), but after some months the performance drops.

That’s because most systems are designed only for “basic treatment”, not for real-life daily variation in chemicals, flow, and load.

Industrial wastewater changes continuously, and if the treatment plant is not upgraded or maintained properly, it will fail.

Why Most ETPs Work Only on Paper

Many ETP systems look perfect in drawings and brochures, but actual performance drops when plant receives real industrial wastewater with changing load, pH shifts, chemical variations, etc.

Common Symptoms of a Weak ETP System

- Outlet COD/TSS fluctuating

- Clarifier overflow & sludge carryover

- Frequent filter choking

- Strong odour and color in treated water

- Higher chemical use with low output

Major Performance Killers in Industrial Plants

1. Improper equalization and mixing

2. Sudden shock load not controlled

3. Over dependence on manual dosing

4. Wrong biological process selection

5. Lack of troubleshooting and preventive maintenance

6. Sludge system neglected

The Smart Way to Improve Output

The most effective way to stabilize treatment is:

1. influent balancing

2. dosing optimization

3. process redesign based on actual sample analysis

4. adding UF/MBR/RO where needed

5. operator training + monitoring 6. Sludge Settling & decanting remove.

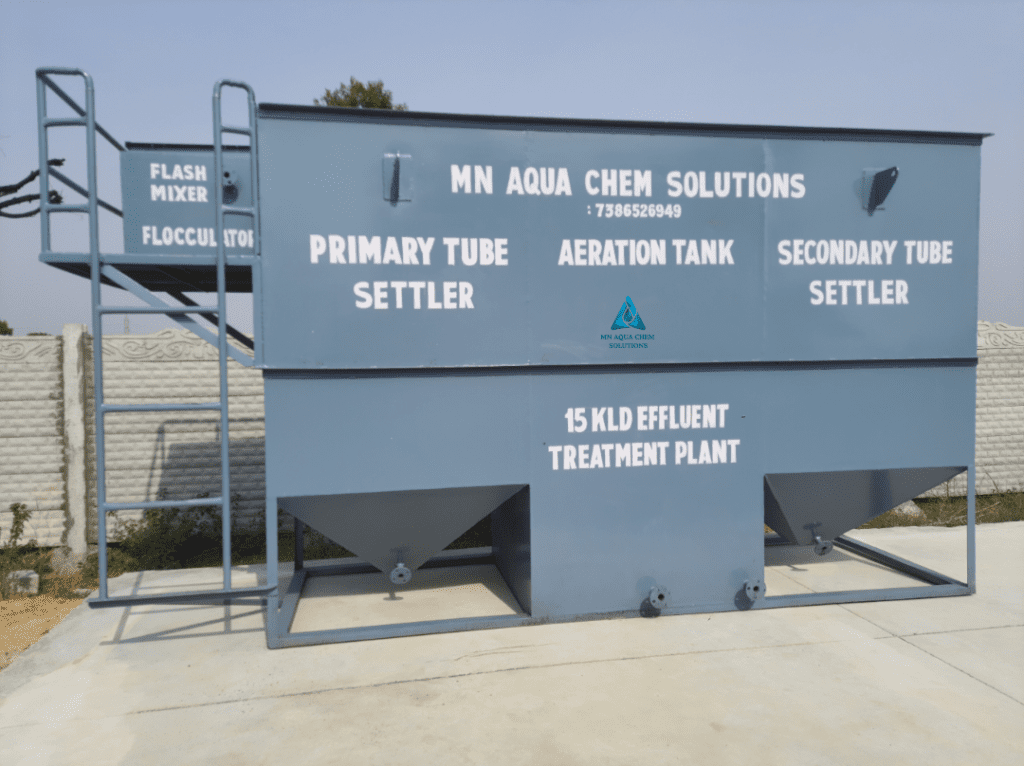

MN AQUA CHEM SOLUTIONS Approach

We focus on:

- improving treated water stability

- reducing chemical & power cost

- ensuring consistent compliance

- enabling reuse and recycling

A properly maintained and upgraded ETP can run smoothly for years with stable output and reduced overall cost.