How water is treated with the help of STP and ETP plant

Wastewater treatment is mainly carried out through two major methods:

- STP (Sewage Treatment Plant)

- ETP (Effluent Treatment Plant)

Both treat wastewater but differ in the type of water treated and end-use.

1. STP (Sewage Treatment Plant)

STP is used for treating domestic wastewater generated from residential buildings, apartments, hotels, hospitals, offices, and institutions.

Sources of Sewage:

- Black Water → Wastewater from toilets (contains fecal matter, urine, pathogens, organic matter, nitrogen, phosphorus).

- Gray Water → Wastewater from bathrooms, washbasins, kitchens, laundry (less contaminated, contains soap, grease, detergents).

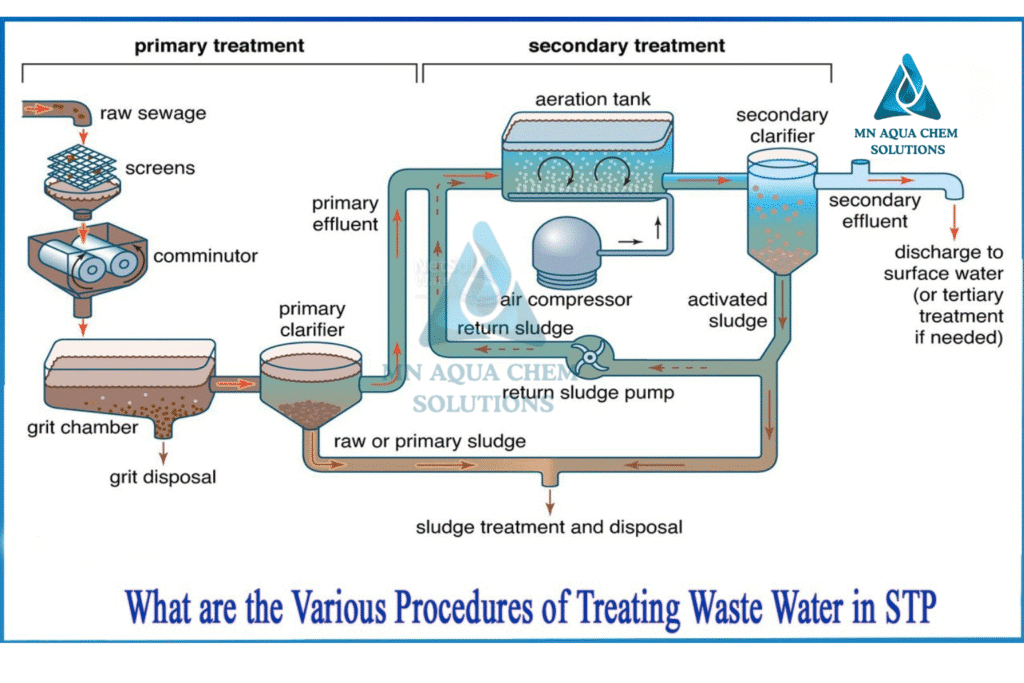

STP Treatment Process:

- Preliminary Treatment

- Screening, grit removal, oil & grease trap.

- Removes plastics, rags, stones, sand.

- Primary Treatment

- Sedimentation tanks allow suspended solids to settle.

- Produces primary sludge.

- Secondary Treatment (Biological)

- Aeration Tank / MBBR / SBR: Microorganisms break down organic matter (BOD, COD reduction).

- Secondary clarifier separates biomass (activated sludge).

- Tertiary Treatment

- Filtration (sand, carbon, UF membranes), disinfection (UV/chlorine/ozone).

- Produces clean water safe for reuse in flushing, gardening, cooling towers.

Key Point: STPs treat black water + gray water and make it reusable for non-potable purposes.

2. ETP (Effluent Treatment Plant)

ETP is used in industries to treat trade effluents before discharge/reuse.

Sources of Industrial Effluents:

- Trade Waste → Non-hazardous industrial wastewater (food processing waste, textile dye water, sugar mill effluents, paper pulp wastewater).

- Hazardous Effluents → Contains heavy metals, toxic chemicals, solvents, acids, alkalis, oils (from pharma, chemical plants, tanneries, electroplating, refineries).

ETP Treatment Process:

- Preliminary Treatment

- Screening, equalization, oil separation, neutralization.

- Primary Treatment

- Chemical coagulation, flocculation, sedimentation.

- Removes suspended solids, color, some metals.

- Secondary Treatment (Biological)

- Aerobic / anaerobic systems depending on wastewater.

- Reduces organic load (BOD, COD).

- Tertiary / Advanced Treatment

- Activated carbon, reverse osmosis, MEE (Multi-effect evaporator), stripping, advanced oxidation, membrane bioreactors.

- Removes toxic chemicals, heavy metals, dissolved salts.

Key Point: ETPs are designed to handle industrial hazardous effluents and comply with Pollution Control Board norms before discharge

Comparison – STP vs ETP

| Aspect | STP (Sewage Treatment Plant) | ETP (Effluent Treatment Plant) |

| Source of Wastewater | Domestic sewage (black water + gray water) | Industrial effluents (trade waste + hazardous effluents) |

| Contaminants | Organic waste, soap, grease, pathogens | Chemicals, heavy metals, dyes, oils, toxins |

| Treatment Focus | Biological + disinfection | Chemical + physical + biological + advanced |

| Reuse Options | Flushing, gardening, cooling tower, construction | Process reuse, safe discharge, zero liquid discharge |

| Regulation | CPCB & local municipal norms | CPCB & SPCB industrial effluent standards |

In Short:

- STP → Treats sewage from toilets, kitchens, bathrooms (black water + gray water).

- ETP → Treats industrial wastewater (trade waste + hazardous effluents).

Looking for a reliable partner in wastewater management? MN Aqua Chem Solutions specializes in STP (Sewage Treatment Plants) and ETP (Effluent Treatment Plants) with advanced technologies like MBBR, SBR, and MBR, catering from 5 KLD to 2000 KLD. From design and installation to operation, maintenance, and chemical supply, we provide end-to-end solutions tailored for residential, commercial, and industrial needs. With local support, quick service, and compliance assurance, MN Aqua Chem ensures sustainable, cost-effective, and efficient wastewater treatment. 💧