Why Sand and Carbon Are Used in RO Plants

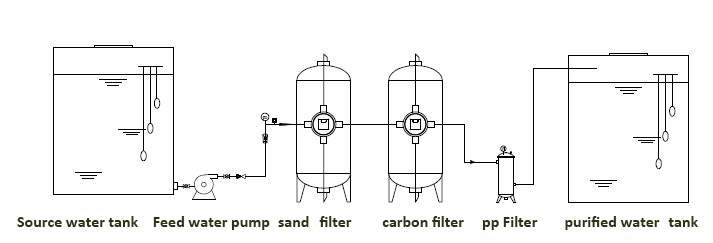

In any Reverse Osmosis (RO) water treatment system, pretreatment plays a vital role in ensuring the RO membranes perform efficiently and last longer. Two key filtration media — Sand and Activated Carbon — are commonly used before the RO unit to remove impurities from raw water. Let’s understand their purpose and importance in detail.

Sand Filter – Removing Suspended Solids

The sand filter is the first stage of filtration in an RO plant. It is designed to remove physical impurities such as:

- Mud, dirt, dust

- Rust particles

- Suspended solids and turbidity

How it works:

Raw water passes through multiple layers of graded sand and gravel. These layers trap suspended particles as the water flows downward. The clean, particle-free water then moves to the next stage.

Benefits of Sand Filtration:

Protects downstream equipment and membranes from clogging.

Reduces turbidity and improves overall water clarity.

Extends the lifespan of carbon filters and RO membranes.

Requires simple maintenance with periodic backwashing.

Activated Carbon Filter – Removing Odor, Color & Chemicals

After sand filtration, water passes through an Activated Carbon Filter (ACF). This filter is made from high-grade carbon material, usually derived from coconut shells or coal, which has a large surface area for adsorption.

What it removes:

Chlorine and chloramines (harmful to RO membranes)

Organic compounds and pesticides

Odor, taste, and color-causing agents

Benefits of Carbon Filtration:

Protects RO membranes from chemical damage (especially from chlorine).

Enhances taste and odor quality of water.

Improves purity by removing trace organic matter.

Helps achieve higher RO efficiency and better product water quality.

Why Both Are Important Together

Both filters perform complementary roles in the pretreatment process:

- Sand Filter → Removes physical impurities.

- Carbon Filter → Removes chemical and organic impurities.

Using both ensures the RO plant receives clean, safe, and pretreated water, preventing fouling or damage to membranes — ultimately resulting in lower maintenance costs and longer equipment life.

Regular Maintenance Is Key

To keep your RO system performing efficiently:

- Backwash the sand filter regularly to remove trapped solids.

- Replace activated carbon periodically to maintain adsorption efficiency.

- Monitor flow rates and pressure drops to detect clogging early.

Conclusion

The combination of Sand and Activated Carbon filters forms the backbone of RO plant pretreatment. They ensure that only clean, pretreated water enters the RO system, protecting your investment and ensuring consistent water quality.

For industrial, commercial, or residential RO system installation and maintenance,

choose MN AQUA CHEM SOLUTIONS – your trusted partner in water treatment excellence.