Purpose of installing ETP Plants in Hospitals

Hospitals consume large volume of water per day for different purposes and also generate large volumes of wastewater that need to be treated.

Sources of effluent generation in Hospitals

Hospital effluent also contains pharmaceuticals, radionuclides, detergents, antibiotics, antiseptics, surfactants, solvents, medicinal medications, heavy metals, radioactive substances, and potentially dangerous and drug-resistant microbes.

There are many units in hospitals which generate wastewater/sewage are listed below:

•Patient wards & administration unit

• Kitchen/canteen and laundry

• Operating rooms and ICUs

• Laboratories

• Radiology & dialysis section

What does hospital effluent consists of?

Hospital effluent may contain large variety of potentially hazardous components including, microbiological pathogens, radioactive isotopes, disinfectants & sterilizants, drugs and their metabolites, chemical compounds, heavy metals and pharmaceuticals etc., at high concentrations and containing some solids disposed by staff and patients. Wastewater from hospitals categorized into as follows:

• Blackwater: It is highly polluted wastewater consists of faecal matter, urine, food residues, toxic chemicals etc.

• Greywater: It is low contaminated wastewater with residues from bathing, washing, laboratory processes and many such.

• Stormwater: Which consist of rainwater from roofs, grounds and other areas in hospitals.

What is the purpose of installing ETP in hospitals?

If the hospital effluent is not adequately handled, it can have a harmful influence on the environment and human health. As a result, selecting an appropriate treatment technology, known as an effluent treatment plant for hospitals is critical.

The primary goal of an Effluent Treatment Plant (ETP) is to remove as many suspended particles and organic matter, from effluent before it is released back into the environment, or reused for other hospital functions. When untreated wastewater contaminates groundwater, it poses substantial health hazards by generating serious infectious illnesses, in those with compromised immune systems.

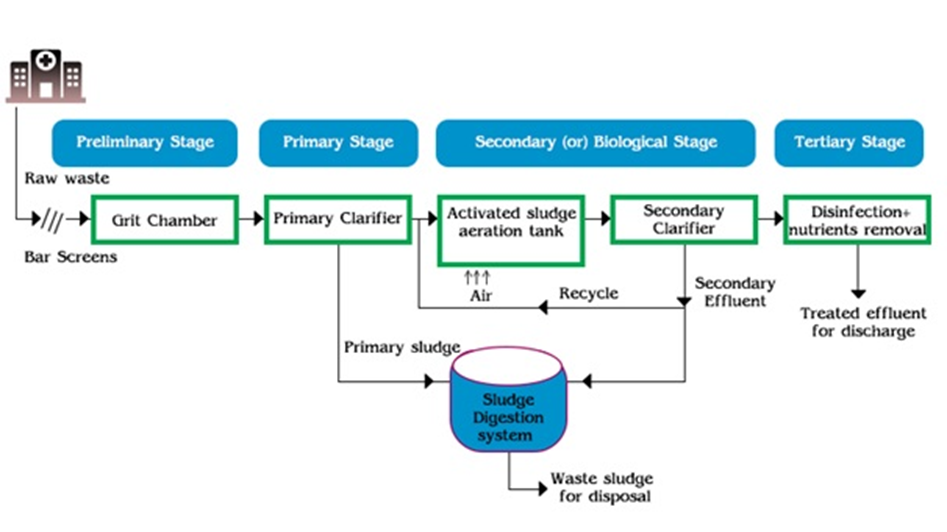

Flow chart of ETP for Hospitals

1. Preliminary Stage: This stage is also called as pretreatment which is the most essential treatment process in most of the ETP. It involves bar screens which comes in variety of shapes and sizes to remove large sized suspended solids like paper, plastics, metals, debris, rags and many such from incoming raw wastewater/sewage. If these materials are not removed then they may cause serious damage to plant equipments. When wastewater enters into grit chamber, it slows down the flow of water and thereby removes sand, grit, sand stones and this process is called as sedimentation.

2. Primary Stage: It uses physical and chemical methods to improve the quality of the wastewater which was not achieved in previous stage. When wastewater enters to sedimentation tank or primary clarifiers, heavier solid particles settle to the bottom of the tank and lighter particles will float up and will be skimmed off from top of the surface using a process called skimming and thereby removing 60-65% of total suspended solids from liquid wastewater. This stage may use grit chamber to remove grit. The settled solid is known as primary sludge which will send to sludge digester for further processing. Now partially clarified water flows on to the next stage.

3. Secondary Stage: This is the stage which can remove about 80-90% of organic matter by using a process called biological treatment methods. Most of the hospital ETP uses “activated sludge process” in which liquid wastewater enters into aeration tank where wastewater mixes with air to encourage the growth of microbes and hence breakdown of organic matter takes place. When aerated water enters into secondary clarifier, floatable matter will be removed and heavier matter settles to bottom which is called as “active sludge” or secondary effluent. Part of the sludge which still contains microbes will be re-circulated back to aeration tank to increase the rate of organic matter decomposition. The left over microorganisms are handled separately in next stage called disinfection.

4. Tertiary stage: This is the final stage which is also known as disinfection stage. This stage removes any residual suspended solids and other materials which were not removed in previous stages. The effectiveness depends on the quality of the water being treated. The major objective of disinfection is to reduce number of microorganisms in the waste water to be disposed into the natural environment. Disinfection technologies consist of ozone, chlorine, and Ultraviolet (UV) rays to eliminate toxic chemicals that exist in the wastewater. This stage removes nitrogen, phosphorous and other toxic contaminants.

MN Aqua Chem Solutions are Manufacturers & Suppliers of Waste Water Treatment Plants and Chemicals. Contact us@ +91 8897657528 to get the estimated price for your custom order.